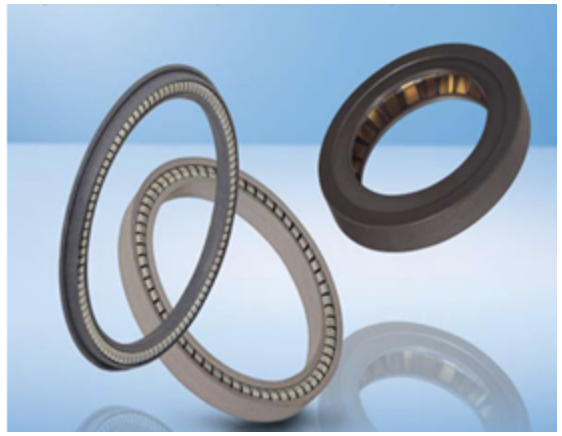

Isakhiwo esisisiseko kunye nomgaqo wamandla okutywinwa kwendandatho yokugcina amandla entwasahlobo iboniswe kulo mfanekiso ulandelayo.Uyilo oluqhelekileyo lusebenzisa i-polymer ephezulu yokusebenza njengemathiriyeli yebhatyi, kwaye ihambelana nemithombo yogcino lwamandla entsimbi enganyangekiyo.Xa i-UPP ifakwe kwi-groove yokutywina njengoko kuboniswe kumzobo, uxinzelelo lwe-deformation lwentwasahlobo luya kunika uxinzelelo lokuqala lokuqinisa umlebe wokutywina, ukwenza uxinzelelo lokuqala lokutywinwa.Ngexesha elifanayo, ngenxa ye-superposition yoxinzelelo lwenkqubo, inkqubo yokutywinwa iyakwazi ukulungelelanisa ukutywinwa phantsi kweemeko ezahlukeneyo zoxinzelelo.I-elasticity engapheliyo yentwasahlobo inokuphinda ihlawule ukugqoka kwempahla yomlomo wokutywina kunye ne-offset kunye ne-eccentricity ye-hardware.

Izinto zokutywinwa kwejacket ngokuqhelekileyo zenziwe nge-polytetrafluoroethylene kunye nezinye iipolymers eziphezulu zokusebenza, ezenziwe ngokujika ngokuchanekileyo.Inokumelana okuhle kakhulu nobushushu kunye nephakathi.

Ubume betywina lokugcina amandla entwasahlobo kwimeko yokusebenza igwema ukungaphumeleli kwe-torsional kunye ne-helical enokuthi yenzeke xa i-O-ring itywinwe ngamandla.Imveliso egqityiweyo nayo inokugcinwa ngokungapheliyo ngaphandle kwengxaki yokungaphumeleli kokuguga.

Iinzuzo zefom yeringi yokugcina intwasahlobo zezi zilandelayo:

I-1, ukuxhathisa kunye ne-static ukuqala ukuxhathisa kuncinci

2, ukuhambelana komgangatho kunye nobubanzi

3, kuluhlu olubanzi lokulungelelanisa ubushushu

4, iimveliso zerabha ucinezelo deformation esisigxina, ukwaluphala, embrittlement kunye nezinye iingxaki

I-5, ukumelana noxinzelelo oluphezulu, ukuxhathisa okunamandla kwe-extrusion

6. Uyilo lwesakhiwo esingaqhelekanga esinqunywe yiteknoloji yokucubungula iguquguqukayo

I-7, iimeko zokungqubuzana ezomileyo

I-8, ixesha lokugcina alinasiphelo

Kwangaxeshanye, kwinkqubo yesicelo sokutywinwa ixesha elide, kukho kwakhona uhlalutyo eziliqela kunye nezicwangciso zokuphucula iziphene amacebo okutywina, ufakelo, umsesane wogcino lwamandla entwasahlobo ngokubanzi kucetyiswa igroove evulekileyo, endaweni yokutywinwa kwe-elastomer yoqobo. iskimu kulula ukuhlangabezana neengxaki zokuhlohla.Ke ngoko, ezo zitywina zifuna ukuba uyilo lwe-groove yesitywina lunokuqinisekiswa kunye nomboneleli wetywina ngexesha loyilo lwesixhobo solwelo.Ngokuqhelekileyo, indlela yokucubungula yeringi yokugcina amandla imisela ukuba iindleko zayo zokuvelisa ziya kuba phezulu kunezitywina ezifanayo ze-elastomer, kodwa ukuphuculwa kokusebenza kwezixhobo zizonke eziswe ngumsesane wogcino lwamandla kunokwenza kakhulu oku kusilela.

Ukusetyenzwa kwe-Hardware, unyango olungaphezulu lwetywina lwe-hardware kunye neringi yokugcina amandla luphezulu kakhulu kunolo lwe-elastomer yemveli, kodwa ukonyuka kweendleko zokusetyenzwa kunokwenziwa luphuculo olungentla ekusebenzeni kwesixhobo ngokubanzi.

Umsesane wokutywina wogcino lwamandla entwasahlobo sisisombululo sokutywinwa esinemfuno ephezulu kakhulu yesicelo, kwaye sinethemba lokukhuthaza ngokuthe ngcembe ukusetyenziswa kweengqikelelo zokutywina ezikumgangatho ophezulu kushishino lwe-fluid kwinkqubo yokusetyenziswa okuqhelekileyo kunye nabasebenzisi, kunye nokukhuthaza uyilo lwetywina kunye nenqanaba lesicelo. yoshishino lwaseTshayina.

Ixesha lokuposa: Jun-28-2023