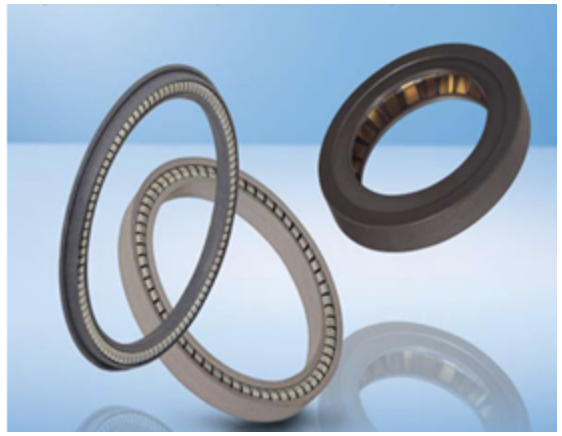

The basic structure and sealing force principle of the spring energy storage ring are shown in the following figure. The typical design generally uses high-performance polymer as the jacket material, and is matched with corrosion-resistant metal energy storage springs. When the UpP is packaged in the sealing groove as shown in the figure, the deformation pressure of the spring will provide the initial pre-tightening pressure of the sealing lip, forming the initial sealing stress. At the same time, due to the superposition of system pressure, the sealing system can adapt to the sealing under different pressure conditions. The permanent elasticity of the spring can also compensate for the wear of the sealing lip material and the offset and eccentricity of the hardware.

The sealing material of the jacket is generally made of polytetrafluoroethylene and other high-performance polymers, which are made by precision turning. It has excellent resistance to temperature and medium.

The shape of the spring energy storage seal in the working state avoids the torsional and helical failures that are prone to occur when the O-ring is dynamically sealed. The finished product can also be stored indefinitely without the problem of aging failure.

The advantages of the spring storage ring form are as follows:

1, friction and static starting friction resistance is small

2, quality compatibility and wide

3, for a wide range of temperature adaptation

4, rubber products compression permanent deformation, aging, embrittlement and other problems

5, high pressure resistance, strong extrusion resistance

6. The non-standard structure design determined by the processing technology is flexible

7, dry friction conditions

8, the storage period is infinite

At the same time, in the long-term sealing application process, there are also several analysis and improvement plans for the shortcomings of such sealing schemes, installation, spring energy storage ring is generally recommended open groove, in the replacement of the original elastomer sealing scheme is easy to encounter installation problems. Therefore, such seals require that the seal groove design can be confirmed with the seal provider during the design phase of the fluid equipment. Generally speaking, the processing form of the energy storage ring determines that its individual production cost will be higher than that of similar elastomer seals, but the overall equipment performance improvement brought by the energy storage ring can greatly make up for this deficiency.

Hardware processing, the surface treatment of the hardware seal with the energy storage ring is generally higher than that of the traditional elastomer, but the increase in processing costs can also be made up by the above improvement in the overall equipment performance.

The spring energy storage seal ring is a sealing solution with extremely high application requirements, and we hope to gradually promote the use of such advanced sealing concepts in the fluid industry in the process of common application with users, and promote the seal design and application level of China’s industrial industry.

Post time: Jun-28-2023