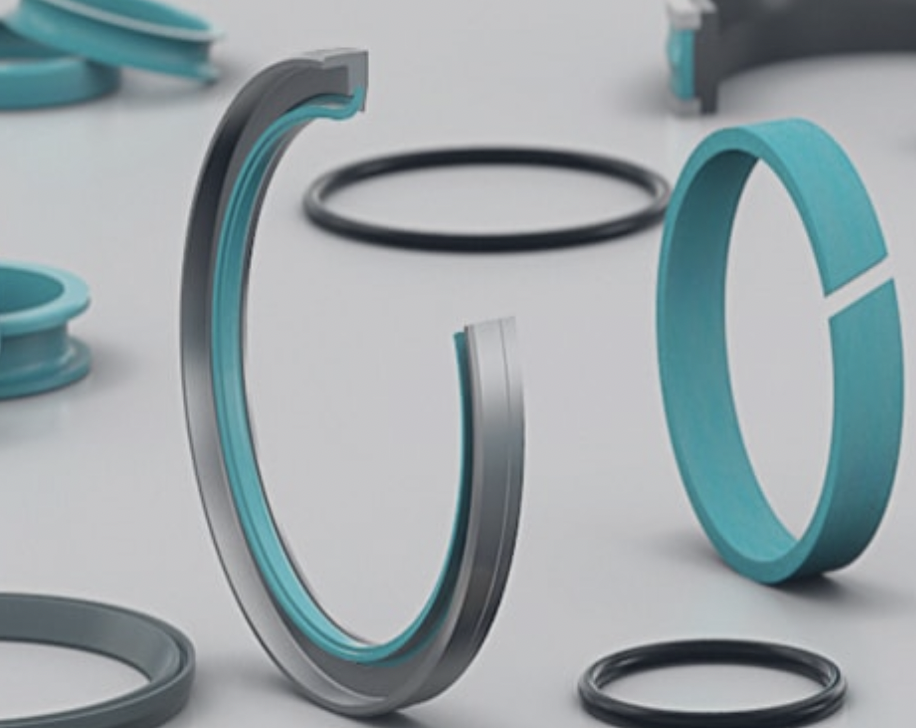

Uninzi lwe-O-ring fractures lwenzeka kwiitywina ezidibeneyo.I-O-rings luhlobo lwe-rubber surface seal kunye ne-cross-section ejikelezayo, i-cross-section yi-O-shaped, ngoko ibizwa ngokuba yi-O-ring, isitywina esisetyenziswa ngokubanzi kwiinkqubo zokutywinwa kwe-hydraulic kunye ne-pneumatic.Xa izinto zetywina zibuhlungu, nangona kunjalo, akukho ukuthotyelwa okungqongqo kwinkcazo ye-welding kunye nonyango lobushushu, ukuqhekeka koxinzelelo kunokwenzeka ngokulula.Okanye ukukhethwa kwezinto ezingafanelekanga kunye neefom zesakhiwo ezingalungiselelwanga ukuhlangabezana nobushushu benkqubo kunye noxinzelelo nazo zingabangela i-fracture phenomena.Ngexesha lokusetyenziswa, umphezulu wokutywina nawo uthambekele ekuqhekekeni kwezinto ezifana ne-hydrogen embrittlement.

Ke ngaba i-O-ring fractures isalungiswa?Impendulo ecacileyo ithi ewe, okokuqala, kufuneka sisuse ngononophelo iintanda, nokuba i-crack encinci kufuneka icace kwaye icoceke, ibone ngqo i-gloss yomzimba, akukho ziphene ukuza kuthi ga ngoku.Izinto ezinothuli ezigqithisileyo kufuneka zisuswe, zixutywe ngentonga yeplastiki ye-welding efanelekileyo kwaye emva koko inqunywe ibe yimfumba ukuyikhusela.Ukuba utyekelo lokuqhekeka kwe-weld egciniweyo yecandelo lezinto eziphathekayo, umaleko we-weld ongezantsi usebenzisa umaleko weplastiki elungileyo yomaleko wenguqu, unokuthintela umaleko womphezulu wokuqhekeka.I-weld kufuneka ibe mfutshane ngokusemandleni ukunciphisa indawo echaphazelekayo yokushisa kunye nokuthintela ukuguqulwa kwendawo yokutywinwa kwe (seal).Ngaphambi kokugquma i-weld ukuya ku-preheat, emva kokuba i-welding insulation ipholile, ikhusela ukuthintela umoya eholweni, ukukhusela umphezulu wokutywina odibeneyo.Emva kokupholisa okucothayo, emva koko ukusetyenzwa kunye nokwenza.

I-ammonia yigesi ekhuselayo engafuntshwa yintsimbi kunye nocingo, kwaye isinyithi kunye ne-alloy kwi-wire ayitshayelwanga.Indawo echaphazelekayo yokushisa incinci kwaye ayibangeli i-slag kunye ne-porosity kwi-overlay layer, kwaye i-deformation incinci.Umbhobho wokuwelda kunye nokutywinwa komhlaba ukugcina i-engile enkulu okanye ethe nkqo, ukuze isisombululo sisoloko sibekwe phantsi kokhuseleko lwegesi yegram, umpu we-welding ukwenza ujingi oluthile, isondlo socingo kufuneka sibe yinto efanayo.Ekupheleni kwesigcwalisi esiphezu komhlaba, ucingo lwe-welding kancinane kufuneka longezwe.Emva koko utsale kancinci kwaye ukhusele umpu ngelixa uphakamisa, emva kokuba ichibi elityhidiweyo libanda kancinane, yeka ukutyisa irhasi ukugqiba ukulungisa.

Ixesha lokuposa: Mar-28-2023