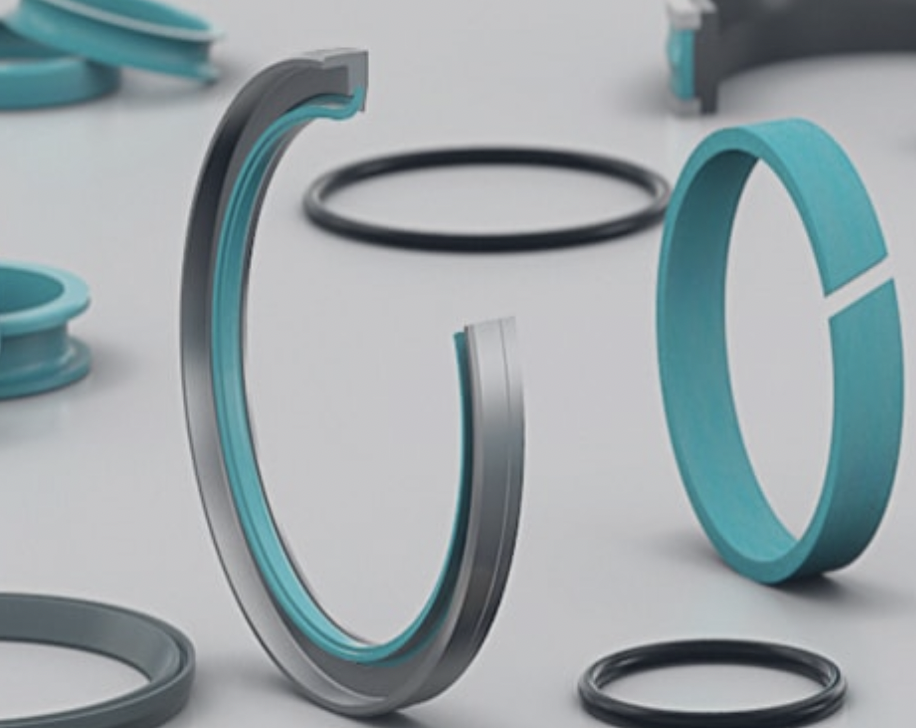

The majority of O-ring fractures occur in overlapped seals. O-rings are a type of surface rubber seal with a round cross-section, the cross-section is O-shaped, so it is called an O-ring, a seal widely used in hydraulic and pneumatic sealing systems. When the material of the seal is brittle, however, there is no strict adherence to welding specifications and heat treatment, stress cracks can easily occur. Or improper material selection and structural forms not designed to meet the system temperature and pressure can also cause fracture phenomena. During use, the sealing surface is also prone to cracking phenomena such as hydrogen embrittlement.

So can O-ring fractures still be repaired? The clear answer is yes, first of all, we should carefully remove the cracks, even a little crack should be clear and clean, straight see the body gloss, no defects so far. The excess dusty material should be removed, primed with a good plasticity welding rod and then trimmed into a heap to defend it. If the stacked weld cracking tendency of the material section, the stacked weld bottom layer using a layer of good plasticity of the transition layer, can prevent the surface layer of cracking. The weld should be as short as possible to reduce the heat affected area and prevent the deformation of the sealing surface of the (seal). Before cladding weld to preheat, after welding insulation slow cooling, defending to prevent the wind in the hall, to protect the welded sealing surface. After slow cooling, then processing and forming.

Ammonia is a protective gas that is not absorbed by the metal and the wire, and the metal and the alloy in the wire are not swept away. The heat affected zone is small and does not cause slag and porosity in the overlay layer, and the deformation is small. Welding nozzle and sealing surface to maintain a larger or vertical angle, so that the solution is always placed under the protection of the gram gas, the welding gun to make a certain swing, the wire feed should be uniform. At the end of the surfacing filler, slightly more welding wire should be added. Then slowly pull away and defend the gun while lifting, after the molten pool is slightly cold, stop feeding gas to complete the repair.

Post time: Mar-28-2023