Featured Products

-

Renewable Design for 301-55 Rubber Ceramic Single Face Water Pump Mechanical Seal

It is widely used in various fields of ordinary industry

Suitable for large size and rough positioning surface matching oil seal hole (note: when sealing low viscosity medium and gas, the static sealing effect between the outer edge of the metal skeleton and the inner edge of the cavity is limited.) -

Fixed Competitive Price Sealcon 208 Double Face Rubber Mechanical Seal for Submersible Pump

Space saving structure

Simple, small installation groove

Due to the use of metal pressing mode of installation, good stability in the groove

When the bearing re-flows oil, the dust scraping lip can automatically open under lower pressure and discharge the dirty oil.

Very wear resistant -

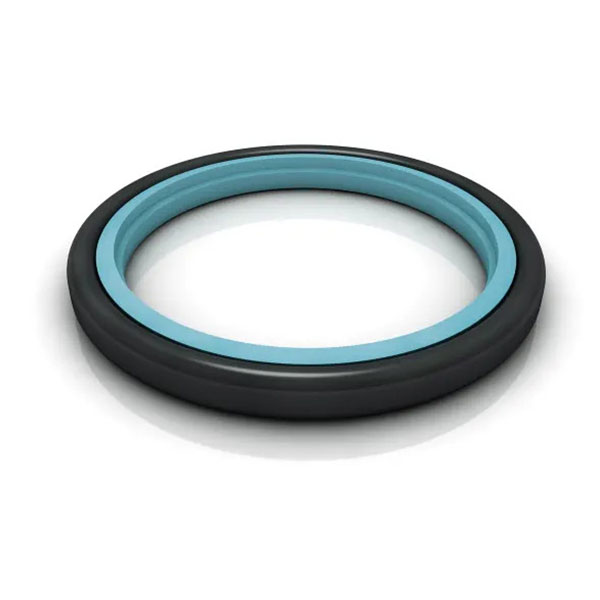

Good User Reputation for U-Shaped Spring Loaded Carbon Filled PTFE Energized Lip Face Seal

Minimal starting and motion friction, even at low speeds to ensure smooth movement, no crawling phenomenon.

Resistant to wear and tear.

crushing.

High temperature resistant.

Due to the high chemical resistance of the seal ring and the choice of o-rings of different materials, FOD seals can be used in almost all media.

Because of the special sealing structure, it has good oil return property. -

High Quality Ts10t Ts10r Seal (John Crane type 10R 10T) Integral/ Insert Rotary Face

Rod seals FM1 is suitable for sealing ring with axial moving piston rod, cavity groove can be exchanged with O-ring cavity groove.

Resistant to harsh media and extreme temperatures

Good dry friction characteristics

Static and dynamic friction values are low -

Factory Free sample DN100 Hydraulic Rotary Union Variseal Face Seal Swivel Joint for Pipeline

Rod seals FM1 is suitable for sealing ring with axial moving piston rod, cavity groove can be exchanged with O-ring cavity groove.

Resistant to harsh media and extreme temperatures

Good dry friction characteristics

Static and dynamic friction values are low -

Factory Free sample DN100 Hydraulic Rotary Union Variseal Face Seal Swivel Joint for Pipeline

Rod seals FM1 is suitable for sealing ring with axial moving piston rod, cavity groove can be exchanged with O-ring cavity groove.

Resistant to harsh media and extreme temperatures

Good dry friction characteristics

Static and dynamic friction values are low -

Factory Free sample DN100 Hydraulic Rotary Union Variseal Face Seal Swivel Joint for Pipeline

Rod seals FM1 is suitable for sealing ring with axial moving piston rod, cavity groove can be exchanged with O-ring cavity groove.

Resistant to harsh media and extreme temperatures

Good dry friction characteristics

Static and dynamic friction values are low -

ODM Factory Vda Rubber Seals / End Face Seals / Water Seals

Abrasion resistance is very good

Resistance to squeeze out

Impact resistance

Small compression deformation

Easy to install for the most demanding working conditions. -

Quots for China Factory E93 Double End Face Shaft Double Sealing Water Pump Mechanical Seal

Mechanical end seals or heavy-duty seals are designed for rotary applications in extremely harsh environments where they can withstand very severe wear and prevent entry of abrasive external media. Mechanical end seals are known as heavy-duty seals, end seals, floating seals, life seals, Toric seals, and multi-cone seals.

-

Wholesale Price Special Purpose for Construction Machinery 18L 20L Package 68 Mobil Hydraulic Oil

Product Advantages

Radial oil seals SC outer edge, Rubber elastomer, Seal lip: Spring loaded, without dust proof lip (applicable to single sealing medium, suitable for higher speed), the sealing lip labial ministry before the end of generated by processing (can better guarantee the precision of the sealing lip), sealing lip bit by mold molding (can better guarantee the precision of the sealing lip), sealing lip bit by mold molding (fit better assurance and shaft surface)

-

China Supplier Ceramic Shaft Sleeve and Seat Rings Mechanical Seal Friction Faces

This seal pack is used for harsh and harsh operating conditions. Currently mainly used

In order to meet the needs of providing maintenance spare parts for old equipment.

V-type sealing group EK type,

The EKV can be used for pistons with pressure on one side, or

A “back to back” installation is used for sealing systems with pressure on both sides of the piston.

• Able to withstand extremely harsh conditions

- Long service life

• Can be optimized to adapt to the use of the corresponding equipment

• Even if the surface quality is poor, it can meet the sealing requirements for a period of time

• Not sensitive to contamination of hydraulic media

• There may be occasional leakage under certain conditions for structural design reasons

Occurrence of leakage or friction. -

Big discounting Mechanical Seal Mcm P25ms/Tt

Each pressing part of the combined seal ring has excellent performance.

friction

Small wear rate

Use two seal rings to prevent extrusion

The initial interference is designed to protect the seal performance at low pressure

Sealed rectangular geometry is stable