Mechanical Face Seals DO applications in extremely harsh environments

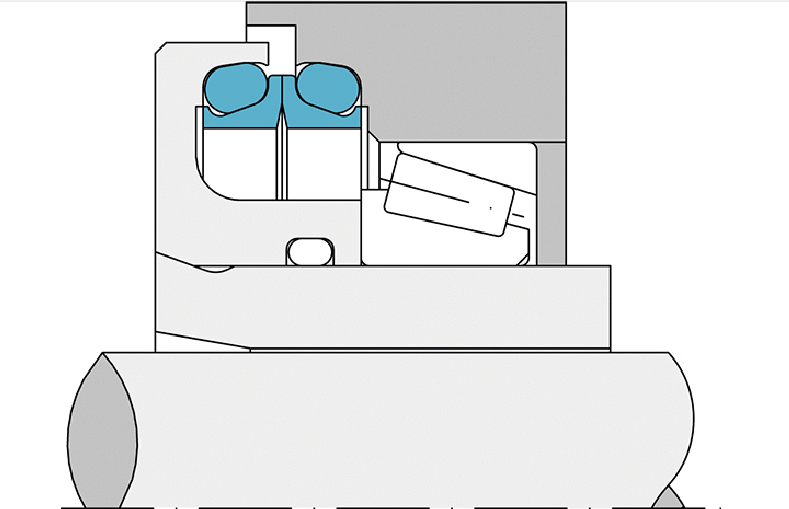

TECHNICAL DRAWING

Type DO is the most common form that uses an O-Ring as a secondary sealing element

Type DO consist of two identical metal seal rings mounted in two separate housings face-to-face on a lapped seal face. The metal rings are centered within their housings by an elastomer element. One half of the Mechanical Face Seal remains static in the housing, while the other half rotates with its counter face.

Mechanical Face Seals are predominantly used for sealing the bearings in construction machinery or production plants operating under extremely arduous conditions and subject to severe wear.

These include:

Tracked vehicles, such as excavators and bulldozers

Conveyor systems

Heavy trucks

Axles

Tunnel boring machines

Agriculture machines

Mining machines

Mechanical Face Seals are proven for use in gearboxes, mixers, stirrers, wind-driven power stations and other applications with similar conditions or where minimized maintenance levels are needed.

Do not use sharp tools such as screwdriver to install the floating oil seal, which may damage the floating oil seal sealing surface and rubber ring.

Install the floating oil seal using a special installation tool.

The installation process is

First dip a small amount of alcohol and wipe the mounting seat cavity to keep it clean. Before placing the rubber trap on the floating seal ring, wipe the rubber ring, the sealing surface of the floating seal ring and the contact surface of the rubber ring with alcohol to prevent dust from entering. Then put the rubber trap on the floating sealing ring and check whether the rubber ring is twisted and deformed at the closing line. After making sure that the clamping line is regular, you can use the installation tool to clamp the floating oil seal and put it on the installation seat cavity. The rubber ring side contacts the seat cavity first and presses down. Finally, check whether the floating oil seal is horizontal after loading, and the position of both sides and the seat cavity are the same height. 4 to 6 points can be observed according to the size of the ring. After completing the above steps, all the installation process of the floating oil seal is completed.

Precautions during installation:

1. The floating seal ring is easy to deteriorate when exposed to air for a long time, so the floating seal is removed when installed. The float seal is very fragile and should be handled with care. The installation site must be free of soil and dust.

2. You are advised to use the installation tool when installing the floating oil seal into the seat cavity. It is common for the O-ring to twist on the floating seal ring, resulting in uneven surface pressure and premature failure, or the O-ring can be pushed to the base and fall off, resulting in oil leakage from the sealing system.

3. Floating seals are regarded as precision parts (especially metal sealing oil surface), so do not use sharp tools to cause damage to floating oil seals. The diameter of the bonding surface is very sharp. Wear gloves when moving.

"The sealing of the floating oil seal is maintained by the ultra-thin oil film generated between the contact surfaces, so it is necessary to apply lubricating oil in the floating oil seal. However, improper lubricating oil types or methods will cause chemical compatible reactions between the rubber ring and the oil, resulting in floating density."

The sealing of the floating oil seal is maintained by the ultra-thin oil film generated between the contact surfaces, so it is necessary to apply lubricating oil in the floating oil seal. However, the improper type or method of lubricating oil will cause chemical compatibility between the rubber ring and the oil, resulting in early failure of the floating seal. Some greases can be used in some cases of slow speed and low vibration, but liquid synthetic oil should still be used as a **. In order to lubricate and cool the floating oil seal well, the lubricating oil must cover 2/3 of the sealing surface. Try to ensure the cleanliness of the oil and sealing system to prevent the loss of the floating oil seal life. Some oils are not compatible with artificial rubber, especially under high temperature conditions, and long-term contact will lead to aging. Therefore, compatibility tests should be done between rubber rings and oil products before oil injection.

Floating oil seal is a key component in the sealing system of mechanical equipment. Once a leakage fault is found during use, it must be checked in time to find out the cause of the fault and solve the problem, so as not to affect the normal use of the equipment. The following is the floating oil seal manufacturers according to years of maintenance floating oil seal analysis and troubleshooting floating oil seal leakage causes and solutions.

Fault cause one: The position of the floating seal is abnormal

Solution: Adjust the limit screw of the actuator such as worm gear or electric actuator to make the valve close correctly.

Fault cause two: There is a foreign body between the floating seal and the seal

Solution: Remove impurities in time and clean the valve cavity.

Fault cause three: The pressure test direction is incorrect, not in accordance with the requirements

Solution: Spin correctly in the direction of the arrow.

Failure cause four: the flange bolt installed at the outlet is stressed unevenly or not compressed

Solution: Check the mounting plane and bolt compression force, and press evenly.

Fault cause five: floating sealing ring upper and lower gasket failure

Solution: Remove the pressure ring of the valve, replace the seal ring and the failed gasket.

DoubleActing

Helix

Oscillating

Reciprocating

Rotary

SingleActing

Static

| Ø – Range | Pressure Range | Temp Range | Velocity |

| 0-800 mm | 0.03Mpa | -55°C- +200°C | 3m/s |