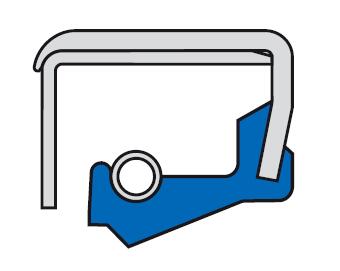

Hydraulic cylinder oil seals SA

TECHNICAL DRAWING

Product Features

Outer edge of oil seal: machined metal

The metal frame

Seal lip lip with spring

Sealing lip section, sealing lip front end from machining

Sealing lip section, sealing lip by mold molding

Recommended

Heavy industry (crane, roll reducer)

Product advantages

Oil Seals SA have shorter, more stable spring seal lips.

Oil Seals SA are widely used in various industrial applications , They are designed for use with large Oil seal holes and rough positioning surfaces. (Note: When sealing low-viscosity media and gases, the static sealing effect between the outer edge of the metal frame and the inner edge of the cavity is limited.) With dust lip, to prevent general and medium dust pollution and the invasion of external dirt.

Role

Oil Seals SA IS a single rotating shaft seal used to seal the rotating shaft. The shorter and more stable spring seal lip increases the pressure range. The rubber seal on the casing ensures a good balance of static seal and thermal expansion. For example, the seal on the light metal casing, the seal on the rough surface, and the seal on the rough surface. Seal of split shell and static seal of gaseous medium. FPM materials are better than NBR at high temperatures, high circumferential velocities, and chemically aggressive media.

DoubleActing

Helix

Oscillating

Reciprocating

Rotary

SingleActing

Static

| Ø – Range | Pressure Range | Temp Range | Velocity |

| 0-2000 mm | 0.05Mpa | -55°C- +260°C | 40m/s |