Featured Products

-

OEM/ODM Manufacturer High Purity Extruded PFA Tube in Chemical Anti-Corrosion

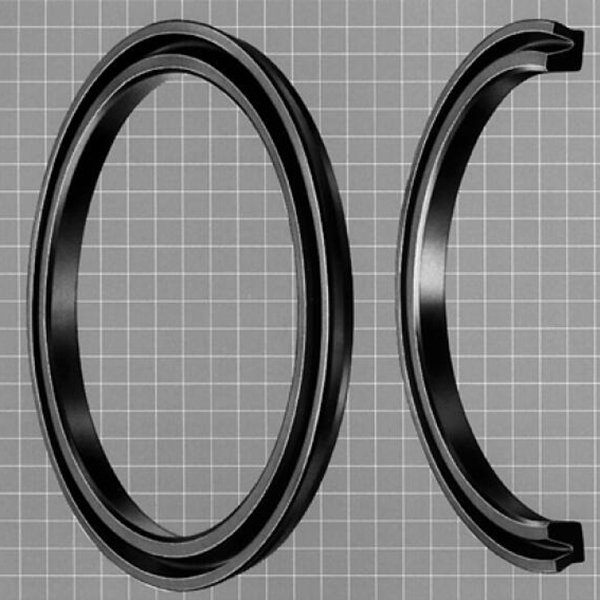

Mechanical end seals or heavy-duty seals are designed for rotary applications in extremely harsh environments where they can withstand very severe wear and prevent entry of abrasive external media. Mechanical end seals are known as heavy-duty seals, end seals, floating seals, life seals, Toric seals, and multi-cone seals.

-

OEM Manufacturer NBR PTFE Bronze STD Step Seal Rod Seal Glyd Ring Hydraulic Cylinder Piston Seal

Space saving structure

Simple, small installation groove

Due to the use of metal pressing mode of installation, good stability in the groove

When the bearing re-flows oil, the dust scraping lip can automatically open under lower pressure and discharge the dirty oil.

Very wear resistant -

China Manufacturer for NBR PTFE Bronze STD Step Seal Rod Seal Glyd Ring Hydraulic Cylinder Piston Seal

The guiding and sealing functions are achieved by the seals themselves in a very small space.

Suitable for use in mineral oil HFA, HFB and HFC fire resistant hydraulic oils (maximum temperature 60 ℃).

Seals are easy to install

Simple integral piston construction.

The special geometry of the NBR seal element allows installation without distortion in the groove. -

Popular Design for NBR PTFE Bronze STD Step Seal Rod Seal Glyd Ring Hydraulic Cylinder Piston Seal

Easy to install: Designed to precise requirements and manufactured to tight tolerances, they will not come off after fitting

Cost reduction: Within a certain limit of clearance, the O-ring will make an effective seal. The use of retaining rings expands the clearance limit and allows loose assembly of moving parts.

There is a shape to obtain better performance: the design of the profile (regardless of the form of installation) ensures improved performance.

Low price: compared to other types of retaining rings, our retaining rings are less expensive

Extends the working life of O-Rings

Improved lubrication

High pressure resistance -

Leading Manufacturer for GDK Seal-PU/NBR Seal Excavator Travel Motor Seal (D-Ring)

Special wear resistance.

Insensitivity to vibration loads and pressure peaks.

Very compression resistance

It has an ideal sealing effect under no-load and low temperature conditions.

Adapted to the most demanding working conditions -

OEM China Imo Pump Seal Type2100 2100K Mechanical Seal Carbon Seal Ring Ceramic Seal Ring Marine Pump Spare Parts

This seal pack is used for harsh and harsh operating conditions. Currently mainly used

In order to meet the needs of providing maintenance spare parts for old equipment.

V-type sealing group EK type,

The EKV can be used for pistons with pressure on one side, or

A “back to back” installation is used for sealing systems with pressure on both sides of the piston.

• Able to withstand extremely harsh conditions

- Long service life

• Can be optimized to adapt to the use of the corresponding equipment

• Even if the surface quality is poor, it can meet the sealing requirements for a period of time

• Not sensitive to contamination of hydraulic media

• There may be occasional leakage under certain conditions for structural design reasons

Occurrence of leakage or friction. -

factory low price 1527 O-Ring Seal Type Mechanical Seal

Mechanical Face Seals or heavy duty seals are specifically engineered for rotating applications in extremely arduous environments where they withstand severe wear and prevent ingress of harsh and abrasive external media. A Mechanical Face Seal is also known as Heavy Duty Seal, Face Seal, Lifetime Seal, Floating Seal, Duo Cone Seal, Toric Seal.

-

Manufacturing Companies for Spare Parts, Auto Parts, O Ring, Rubber Part, Valve Steam Seal, Oil Seal with Elring Brand

Mechanical Face Seals or heavy duty seals are specifically engineered for rotating applications in extremely arduous environments where they withstand severe wear and prevent ingress of harsh and abrasive external media. A Mechanical Face Seal is also known as Heavy Duty Seal, Face Seal, Lifetime Seal, Floating Seal, Duo Cone Seal, Toric Seal.

-

Professional Design Different Size O Ring Abrasion Resistant O Rings PTFE NBR FKM Silicone PU HNBR Black Green Brown White Red O Ring Seals

The four lobed design provides twice the sealing surface of a standard O-RING.

Because of the double-sealing action,less squeeze is required to maintain an effective seal.The reduction in squeeze means less friction and wear which will increase service life and reduce maintenance costs.

Very good sealing efficiency. Due to an improved pressure profile over the X-Ring cross-section, a high sealing effect is achieved. -

2019 High quality NBR/FPM/Sir/Acm/PU/Ptef/NBR Front Crankshaft Skeleton Drive Radial Shaft O Ring SKF/Viton/Rubber/Silicone Hydraulic Oil Seal for Hydraulic Pump/Motor

Mechanical end seals or heavy-duty seals are designed for rotary applications in extremely harsh environments where they can withstand very severe wear and prevent entry of abrasive external media. Mechanical end seals are known as heavy-duty seals, end seals, floating seals, life seals, Toric seals, and multi-cone seals.

-

100% Original Lunch Box Glass Jar Food Grade LFGB Certified Extrusion Joint Silicone Lid Seal O Ring

Small installation groove, good sealing performance.

The operation is very stable due to the geometry of the sealing lip that holds the lubrication film best, and due to the use of rubber materials that have proved suitable on pneumatic equipment.

Small structure, so static and dynamic friction is very low.

Suitable for dry air and oil-free air, initial lubrication during assembly plays an important role in long working life.

Lip seal structure ensures proper function.

Easy to fit in sealed groove.

It is also suitable for cushioning cylinders. -

OEM Supply Precision Tungsten Carbide Mechanical Seal Ring Valve Seat

This seal pack is used for harsh and harsh operating conditions. Currently mainly used

In order to meet the needs of providing maintenance spare parts for old equipment.

V-type sealing group EK type,

The EKV can be used for pistons with pressure on one side, or

A “back to back” installation is used for sealing systems with pressure on both sides of the piston.

• Able to withstand extremely harsh conditions

- Long service life

• Can be optimized to adapt to the use of the corresponding equipment

• Even if the surface quality is poor, it can meet the sealing requirements for a period of time

• Not sensitive to contamination of hydraulic media

• There may be occasional leakage under certain conditions for structural design reasons

Occurrence of leakage or friction.